Posted in: Comics | Tagged:

Dennis Barger on Diamond Comic Distributors' New Boxes

Dennis Barger of QuickStop and Wonderworld Comics in Maryland is a comic book retailer who has had a fractious relationship with Diamond Comic Distributors over the years. Including one of his biggest bugbears, damage to comics and the like caused by shipping. And his disdain for Diamond's methods and track record, including their new cardboard boxes designed to reduce damage in transit.

Back in 2016, Barger wrote about how Diamond needed better boxes. He specifically targeted the larger "400" containers, saying that "We need to talk about getting less dollar amounts in these boxes." and advises on a system that wouldn't have comics, books and fragile items right up against the corner of such boxes.

Last week, Diamond Comic Distributors, stated they were introducing a redesigned shipping box focusing on Diamond's 200-count, 400-count, and 200/400-count combo boxes for shipping comic books and other merchandise, with the goal to drastically reduce the amount of shipper-related damages through a stronger structural integrity of the box. They said that the new boxes will be in use starting with retailer shipments for December 18th release items. Which is this week. That retailers may see a mixed shipment of old and new boxes for a few weeks, as old inventory is depleted, but with all shipments by late December using the new, stronger box structure.

Featuring a completely flat interior, with no flaps or tape on the bottom, the new box design allows comics to sit evenly inside the box, thus reducing the potential for bends and other damages to comic books. Furthermore, the new design boasts a considerable structural improvement over the existing box when compared in a burst test. A burst test is a pressure test used to determine the maximum weight at which a component will "burst" or fail. The new design's point of failure came under much more weight than the existing box: the existing shipping box reaches its first point of failure at 737 pounds of pressure, whereas the new boxes reach its first point of failure at 3,200 pounds of pressure, representing a 335% structural improvement. The existing box reaches its second point of failure at 2,200 pounds of pressure, whereas the new design reaches its second point of failure at 3,500 pounds of pressure, representing a 56% structural improvement.

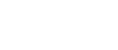

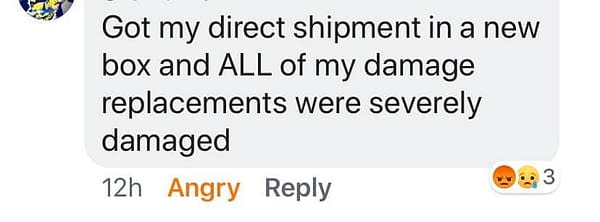

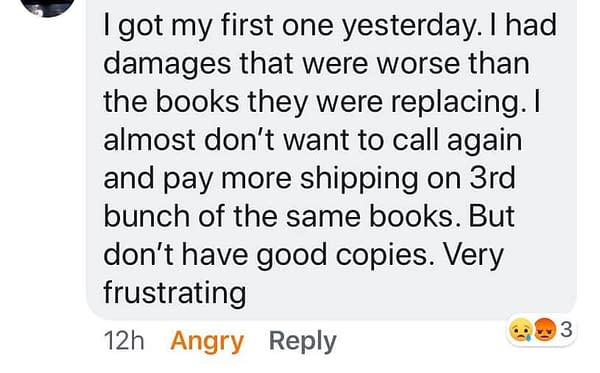

However, Dennis didn't see solutions. He posted on Facebook, including anonymous screencaps from other retailers.

And the reviews of the new fool proof diamond boxes are in…. and exactly what I said they'd be… it's not the box stupid, it's the packing and lack of buffer zones #tenmillionwellspent #thanksdiamond

And then this week he got hold of one of the boxes himself. And did a little filming…

I'm sure not all Diamond customers had this experience – anyone else out there like to share theirs?