Posted in: Comics | Tagged: Comics, entertainment, kickstarter

Working With Multiple Manufacturers To Get Your Self-Published Project Delivered

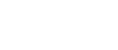

Paul Roman Martinez writes,

I've finished four kickstarter projects so far in the comics and tabletop games categories. I've also produced many other manufacturing projects without using crowdfunding. Right now, I'm working on my first project not in those categories—a USB drive shaped like a vintage Goodyear-Zeppelin airship design I hope to one day distribute digital copies of my books on. Here's the link for that. You have until Sept 16th to help get that project off the ground.

Along the way, I've dealt with dozens of factories and websites to get the prices and quality I need. The difficulties inherent in producing with crowdfunding mean you are often managing several different manufacturers, sometimes in completely different countries, and you are trying to get them all to deliver around the same time. I've worked with some great manufacturers and some terrible ones. On the Kickstarter campaign to print the second edition of my first graphic novel, I used nine different manufacturing sources! Of course, once you include the postage boxes, shipping with USPS, and buying labels from Paypal, the count ended up at a dozen providers I had to work with just to deliver that single project on time.

1. Finding manufacturers

So how do you find all these providers?

Finding manufacturers can be challenging, depending on your industry. In book manufacturing, providers are fairly easy to find. They often approach me at different comic book conventions and ask me to get quotes from them. But that is not the case in other industries. One of the most difficult things I've ever produced was a resin toy walking tank statue. I produced a prototype a couple years ago and started asking a lot of people where they manufactured their toys. I got the same answers every time: "I can't tell you that" or "You can't afford them." That was a ridiculous answer to me. I'm producing a toy—a unique item based on my IP—I'm not producing nails at your nail factory that will take away sales from you! As a result, I can't stand talking to people who produce toys and figures anymore. They are so unnecessarily secretive. Instead of building a community of indie toy creators who can help each other, they needlessly try to hide their sources. I've actually had people ask me for advice in marketing their toys and then, when I ask who is manufacturing them, they refuse to tell me. It's unbelievable.

Another area I've manufactured in is board games. Most games actually feel like you're already producing several different products due to the different bits and pieces that go into making a game. A good manufacturer, like Panda Games who I used for my ASSAULT: 19XX board game, will outsource any bits you need from other factories at a price that works for your budget. In the picture above, I point out every manufacturer I used to get my graphic novels produced. Some are domestic; some are foreign; some are right in the town where I live!

Ask people who produce things you like where they got it printed. When people ask me, I always tell them. Oh, and that toy I produced that took years to find a manufacturer, I printed the company's name right on the box!

2. Getting quotes

When getting quotes for manufacturing, it is important that you include as many details as you can to get an accurate price quote. You'll need to know approximately how many you want. I usually get a quote for two ranges, like 500 qty and 1000 qty or 1000 qty and 1500 qty. This helps me see where the price breaks are so I can make a better decision about how much funding I will need to raise. Of course, sometimes you get locked into using a company because they have a high reputation in the field, as was the case with Bicycle. But this is never a desirable position to be in. If you are only getting one quote, then you could be costing yourself thousands of dollars. I have had quotes for the exact same product come in at 95% less from a competing manufacturer. Yes, you read that right, 95%!

Another reason for getting at least two competing quotes is if you need to switch manufacturers at some point in the process. I had a book manufacturer once stop responding to my emails on a $25,000 dollar printing project. I am a single person producing all these things with my own money or backers' money; I can't risk getting it wrong. So when that book company took too long to respond to my emails, I dropped them and went with my second quote. The first company was blown away that I dropped them. They called me trying to get me back, but by the time they did, I had already switched companies and signed a contract with the new one. The first company had not yet even given me a contract to sign! I'm glad I switched, and my new company has done great work for me ever since. They've always responded to my emails and messages in a timely manner. In the case of Bicycle, there were two occasions where I wanted to fire them and go with another quote, but I hadn't gotten a second quote! I knew I had to use Bicycle because they have been the industry standard, but they were terrible at answering emails. I couldn't even get them to answer the phone. I desperately tried to get a detailed, itemized quote but couldn't. Now I've reached out to other playing card manufacturers, such as the Legends Playing Card Company, and I have some options in my pocket for my next playing card deck or a reprint of my Flight Deck.

Get multiple quotes and don't be backed into a corner. Don't be afraid to tell a company the quote you got and see if they can match it.

3. Ordering Prototypes/Making Your Own

The more complicated your project, the more likely you will have to order one, if not multiple, prototypes. And yes, you will have to pay for these in advance. With books, this is a built-in cost of the production process, and they will send you proofs that you can pour over to look for mistakes or page order errors. With manufactured products like the deck holder I designed for my Flight Deck playing cards, I always order a prototype early so I can tweak the design. I ended up going through three separate and distinct prototypes on that single piece trying to get it perfect. And every time, I had to pay a new plate fee and prototype fee. But it was worth it because the final product is something I'm very proud of. However, when I printed my playing cards, I didn't order a single prototype and the decks came out perfect. And with "gang printers" (cheap online digital print companies that group projects together for printing to get cheaper prices), you usually don't have the luxury of getting a prototype. Right now, I'm producing a prototype for my Airship Flash Drive project. The main thing I'm looking for there is a small hole in the bottom I need to fit on a flight stand that I'm getting from a different factory. One factory wanted $8 each for a small acrylic flight stand; one factory wanted .50 cents each. Which one do you think I went with?

Paying for a prototype is almost always worth the money, especially if it is your first time making a certain type of product. Many manufacturing companies will include it in your overall price. Make sure and analyze every detail of that prototype; it's your last chance to make changes!

4. Scheduling Everything to Come Together

If you are manufacturing something in the United States, the time it takes from final approval to delivery can be less than four weeks. If you are producing something overseas, it can take one to three months from final approval to delivery, especially if it's your first time ordering something manufactured from overseas. The odds of your shipment getting held up at customs is high. And when something is in customs waiting for inspection, you have no way of knowing when it will be released. It'll be done whenever they get to it. Even then, you can be affected by things you never thought you'd care about, like dock strikes or tropical storms. Yes, these surprises can add weeks to your schedule. During one of my book orders, there was a dock worker strike at the Long Beach Port that held up my books for an extra week.

Plan ahead; schedule your shipments to arrive when you need them. Things that ship locally can wait until the very end. Work on those foreign print projects first!

5. Reviewing Your Product/Quality Check

No matter who makes your product for you, there are going to be mistakes and misprints. Every single book or toy I get that isn't pre-shrinkwrapped from the factory gets a good once over from me. If I notice an error or a defect, I set it aside. If those defects start piling up, then I take a picture and send it to the factory for some kind of discount or reprint. Sometimes I've noticed errors and realized it was because of the way I designed something. This is another reason why you should really take time and go over your prototype well from multiple angles!

Factories make mistakes. Double check at least a few cases of your product to make sure everything came out the way you thought it would.

Manufacturing a book can be daunting. Manufacturing a dozen products to fulfill one kickstarter campaign can quickly turn into a nightmare. Start early; space products out on your calendar; and respond quickly to emails from your manufacturer. Working with multiple manufacturers is manageable if you stay calm and organized!